- europages

- >

- 企业 - 供货商 - 服务商

- >

- carbon steel

NINGBO FRIMA INDUSTRY CO. LTD.

中国

Description: •Precision machined components, Machining service, CNC precision machining, Stainless steel precision machined parts manufacturer •Material to process: aluminum, stainless steel, carbon steel, brass •Precision: 0.010-0.002mm •Equipments: CNC lathe, processing center, miller, cylindrical bore grinder, surface form grinder, punching machine, etc. •Surface treatment: zinc, nickel, anodized, polishing •Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. •We are able to supply Precision machined components, mechanical parts machining, surface treatment such as anodize and plating according to our customers’ requirement. •FOB Price: USD0.05-10/Piece •MOQ: 1000PCS for each part •Packaging details: inner plastic bag, outer standard carton box •Delivery time: 25-35 days Notes: we manufacture precision machined components in compliance with customer’s designs.

请求报价

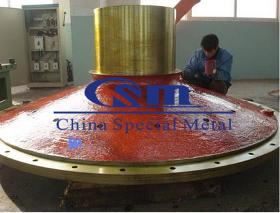

SHANGHAI SPECIAL METAL CO., LTD

中国

Shanghai Special Metal Co., Ltd supplies ball mill head. The materials of mill head are normally selected low carbon steel and low alloy steel. It's produced by casting, used in ball grinding mill, including the feed end and outlet end, our head/cap for the bellow ball grinding mill.

请求报价

SHANGHAI SPECIAL METAL CO., LTD

中国

Weight: 20-150T Applicable device: vertical mills, mineral slag vertical mills, cement vertical mills, steel slag vertical mills, nickel slag mills, raw material vertical mills and coal vertical mills. Application: Cement, building material, chemical, coal, electricity, metallurgy, non metallic mine and others Customizable: Yes Main materials: Plain carbon steel, Si-Mn steel Product Introduction Mill table is an important part of cement vertical mill and slag vertical mill. Mill table consists of resistance loop, liner plate and base. SHANGHAI SPECIAL METAL CO., LTD optimizes casting technology of mill table, applies the most advanced molding - sodium silicate-bonded sand. Our technology overcomes structural shortcomings of traditional methods. The advantages are base of mill table is uniformly stressed; nip angle between mill table and mill roller is enlarged, good anti-corrosion of no wear-resisting face. SHANGHAI SPECIAL METAL CO.

请求报价

SHANGHAI SPECIAL METAL CO., LTD

中国

Aluminum electrolyzer is the main equipment of Cryolite- Aluminum Oxide mix in the fused salt solution in order to electrolysis the fine aluminum to get the aluminum ingot. Electrolytic aluminum anode steel claw/yoke is also called electrolysis claw/yoke. There are several types of claws, such as parallel three claws, four claws, stereoscopic four claws, six claws, eight claws, double anode steel claw etc. The steel claw is connected to the copper bar to consist of Anode. Material for the claw/yoke is an approved low carbon steel, which is similar the following standards: AS 2074-2003 Grade C2 AISI 1010, 1008 or 1006

请求报价

ANHUI JOTUN POLISHING MACHINE COMPANY

中国

This is JT-2-in-1 tank shell and dish head surface polishing machine,which can polish tank shell inside and outside surface. Producting workpiece: Material:Metal(stainless steel,carbon sheel,etc.) Min and max diameter:200-5000mm, Min and max thickness:>1mm Min and max length:300-6000mm. Weight:1/2/3/5/10Tons. Surface roughness:Ra≤0.25μm Material:Metal(stainless steel,carbon sheel,etc.) Min and max diameter:400-5000mm, Min and max thickness:>1mm Min and max Height/Depth:800mm. Weight:1/2/3/5/10Tons. Surface roughness:Ra≤0.25μm Shipment port:Shanghai port. Delivery time:30 working days Payment: T/T, L/C Warranty: 12months. For more,please Contact us, www.jotunpolishing.com Tel:+86 19856555106(whatsapp/wechat) Email:sales04@jotunmachinery.com

请求报价

HAN SONG M&T

韩国

[Product Description] A-PRO series is available for cutting general-purpose and variety of workpiece materials such as pre-hardened steel, alloy steel, carbon steel, heat-resistant alloy steel, and reinforced plastic (below HRC 50). It is also suitable for using in shrink fit chucks due to its shape design to prevent the breakage of cutting edge. [Product Specification] Flat end mill : D0.4 ~ D20 + Various effective length / total length Ball end mill : D0.4 ~ D20 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2ARE, 2APE, 2AEL, 4APE, 4AEL, 4APL Ball : 2ARB, 2ASB, 2APB C/R : 2ARR, 2ACR, 2ALR, 4ARR, 4ACR, 4ALR [Product Use] * Suitable for various work materials (HRC below 45), pre-hardened steel, steel, carbon steel, mold steel * Strong wear-resistance and minimizing chipping by adapting A-pro coating * Excellent surface roughness of work pieces due to optimized cutting edge

请求报价

HAN SONG M&T

韩国

[Product Description] A-PRO series is available for cutting general-purpose and variety of workpiece materials such as pre-hardened steel, alloy steel, carbon steel, heat-resistant alloy steel, and reinforced plastic (below HRC 50). It is also suitable for using in shrink fit chucks due to its shape design to prevent the breakage of cutting edge. [Product Specification] Flat end mill : D0.4 ~ D20 + Various effective length / total length Ball end mill : D0.4 ~ D20 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2ARE, 2APE, 2AEL, 4APE, 4AEL, 4APL Ball : 2ARB, 2ASB, 2APB C/R : 2ARR, 2ACR, 2ALR, 4ARR, 4ACR, 4ALR [Product Use] * Suitable for various work materials (HRC below 45), pre-hardened steel, steel, carbon steel, mold steel * Strong wear-resistance and minimizing chipping by adapting A-pro coating * Excellent surface roughness of work pieces due to optimized cutting edge

请求报价

HAN SONG M&T

韩国

[Product Description] X-PRO series is for milling carbon steel, low alloy steel and cast iron. It is optimized for roughing by applying a new shape cutting edge for reducing cutting force and improving wear resistance. [Product Specification] Flat end mill : D3 ~ D16 (2Flute, 4Flute) Roughing end mill : D3 ~ D16 (3Flute, 4Flute) [Product Model] Flat : 2XPE, 4XPE, 4XREV, 4XPEV Roughing : 3XOE, 4XOE [Product Use] * X pro series is suitable for Roughing by chip breaker and to cut HRC below 50. * Strong wear-resistance by adapting X-pro coating. * Special design of cutting edge minimizes fracturing. * Excellent work surface by deep ship pocket.

请求报价

HAN SONG M&T

韩国

[Product Description] H-PRO series can be used in a wide range from general steel to high-hardness steel, and it is designed for high-hardness and high-speed milling. It is suitable for cutting carbon steel, alloy steel series, molds and mold parts, and is useful for ultra-precision machining by applying high-precision tolerances. [Product Specification] Flat end mill : D0.05 ~ D25 + Various effective length / total length Ball end mill : D0.1 ~ D20 + (same as above) C/R end mill : D0.2 ~ D20 + (same as above) Inner C/R end mill : D0.5 ~ D5.9 + (same as above) High speed milling end mill : D0.8 ~ D12 + (same as above) [Product Model] Flat : 2HRE, 2HPE, 2HLE, 4HRE, 4HPE, 4HLE, 4HHE, 6HPE Ball : 2HRB, 2HSB, 2HPB, 3HPB, 4HPB, C/R : 2HRR, 2HCR, 4HRR, 4HCR, 4HIT Inner C/R : 2IRC, 4IRC [Product Use] H pro series is suitable for High hardened steels (HRC 45~55) and pre-hardened steel. Strong wear-resistance and minimizing chipping by adapting H-pro coating.

请求报价

HAN SONG M&T

韩国

[Product Description] H-PRO series can be used in a wide range from general steel to high-hardness steel, and it is designed for high-hardness and high-speed milling. It is suitable for cutting carbon steel, alloy steel series, molds and mold parts, and is useful for ultra-precision machining by applying high-precision tolerances. [Product Specification] Flat end mill : D0.05 ~ D25 + Various effective length / total length Ball end mill : D0.1 ~ D20 + (same as above) C/R end mill : D0.2 ~ D20 + (same as above) Inner C/R end mill : D0.5 ~ D5.9 + (same as above) High speed milling end mill : D0.8 ~ D12 + (same as above) [Product Model] Flat : 2HRE, 2HPE, 2HLE, 4HRE, 4HPE, 4HLE, 4HHE, 6HPE Ball : 2HRB, 2HSB, 2HPB, 3HPB, 4HPB, C/R : 2HRR, 2HCR, 4HRR, 4HCR, 4HIT Inner C/R : 2IRC, 4IRC [Product Use] H pro series is suitable for High hardened steels (HRC 45~55) and pre-hardened steel. Strong wear-resistance and minimizing chipping by adapting H-pro coating.

请求报价

HAN SONG M&T

韩国

[Product Description] H-PRO series can be used in a wide range from general steel to high-hardness steel, and it is designed for high-hardness and high-speed milling. It is suitable for cutting carbon steel, alloy steel series, molds and mold parts, and is useful for ultra-precision machining by applying high-precision tolerances. [Product Specification] Flat end mill : D0.05 ~ D25 + Various effective length / total length Ball end mill : D0.1 ~ D20 + (same as above) C/R end mill : D0.2 ~ D20 + (same as above) Inner C/R end mill : D0.5 ~ D5.9 + (same as above) High speed milling end mill : D0.8 ~ D12 + (same as above) [Product Model] Flat : 2HRE, 2HPE, 2HLE, 4HRE, 4HPE, 4HLE, 4HHE, 6HPE Ball : 2HRB, 2HSB, 2HPB, 3HPB, 4HPB, C/R : 2HRR, 2HCR, 4HRR, 4HCR, 4HIT Inner C/R : 2IRC, 4IRC [Product Use] H pro series is suitable for High hardened steels (HRC 45~55) and pre-hardened steel. Strong wear-resistance and minimizing chipping by adapting H-pro coating.

请求报价结果来自

Carbon steel - 進出口搜索结果的数量

12 产品企业类别